Add to Cart

PRODUCT DESCRIPTION

To determine the heat load for a Plate Heat Exchanger (PHE), you need to calculate the amount of heat that needs to be transferred between the hot and cold fluids. The heat load can be determined using the following formula:

Heat Load = Mass Flow Rate x Specific Heat Capacity x Temperature Difference

Where:

Mass Flow Rate: The mass of fluid flowing per unit time through the heat exchanger.

Specific Heat Capacity: The amount of heat required to raise the temperature of a unit mass of the fluid by one degree Celsius.

Temperature Difference: The temperature variance between the hot and cold fluids entering and exiting the heat exchanger.

By calculating the heat load, you can determine the required heat transfer capacity of the Plate Heat Exchanger to meet the thermal demands of the system.

To calculate the mass flow rate for a Plate Heat Exchanger (PHE), you can use the following formula:

Mass Flow Rate = Density x Velocity x Area

Where:

Density: The density of the fluid flowing through the PHE (typically in kg/m³).

Velocity: The velocity of the fluid flow through the PHE (typically in m/s).

Area: The cross-sectional area through which the fluid flows (typically in m²).

By multiplying the density of the fluid by the velocity of flow and the cross-sectional area, you can determine the mass flow rate of the fluid passing through the Plate Heat Exchanger

To choose a Plate Heat Exchanger (PHE), consider the following factors:

Application Requirements: Determine specific application needs, including fluid flow rate, inlet and outlet temperatures, operating pressure, and the type of fluid being processed.

Plate and Gasket Materials: Select suitable materials for plates and gaskets based on chemical compatibility, corrosion resistance, and operating temperature.

Heat Transfer Efficiency: Consider the heat transfer efficiency of the PHE concerning the fluid type and temperature difference between fluids.

Maintenance Ease: Evaluate the ease of maintenance of the PHE, including accessibility for cleaning and part replacement.

Cost and Energy Efficiency: Take into account the initial cost of the equipment as well as operational costs associated with energy consumption.

Size and Capacity: Choose a PHE with the appropriate size and capacity to meet application demands, considering available space constraints.

By considering these factors and consulting with a heat exchanger specialist, you can make an informed choice that meets the specific needs of your application.

These are just a few examples of the many applications where plate heat exchangers play a crucial role in efficient heat transfer processes.

| Model | DLXU03/DLXM3 |

| Plate Thickness | 0.5/0.6mm |

| Plate Hole Size | 50mm |

| Maximum Throughput | 45m3/h |

| Adapter Pipe For Large-diameter | DN50 |

| Working Pressure | 1.0/1.6MPa |

| Test Pressure | 1.3/2.1Mpa |

| Model | Standard maximum flow rate m3/h | Maximum number of assembled pieces N | Clamping size A | Maximum length L1 |

| VH05 | 45 | 167 | N*(300+X) | 1390 |

| VN5 | 45 | 211 | N*(2.0+X) | 1390 |

| Product parameter of gasketed plate heat exchanger | |

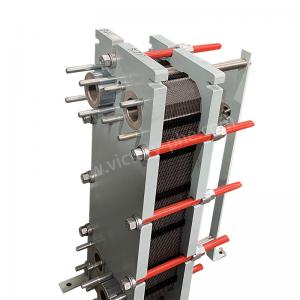

| Item | plate heat exchanger |

| Brand | Victory |

| Plate material | Titanium/Nickle/hastolly/Stainless steel 0.5mm 0.6mm 0.7mm 0.8mm 1mm |

| Gasket material | NBR HNBR EPDM HEPDM VITON FKM Silicone |

| Frame material | Painted Carbon steel |

| Color of frame | blue or customed color |

| Connection type | flange or thread |

| Flange standard | ANSI ASME BS BA JIS DIN GB ISO |

| Tightening bolt | M24 M30 M39 |

| Design pressure | highest 20mpa, lowest 10Mpa |

| Work pressure | normal 12.5Mpa |

| MOQ | 1 set |

| Package | polywood case |

| Warranty | one year |

| OEM | Can make replacement |

Q:What means hot fuil flow rate in phe?

A:The hot fluid flow rate in a Plate Heat Exchanger (PHE) refers to the volume of the hot fluid that flows through the hot side of the heat exchanger within a specific period of time. This parameter is crucial in determining the heat transfer capacity and efficiency of the PHE. By knowing the hot fluid flow rate, you can calculate the heat exchange capacity and ensure that the heat exchanger meets the thermal requirements of the application.

Q:What means cold fuil flow rate in phe?

A:The cold fluid flow rate in a Plate Heat Exchanger (PHE) refers to the volume of the cold fluid that flows through the cold side of the heat exchanger within a specific period of time. This parameter is essential for determining the heat transfer capacity and efficiency of the PHE. Knowing the cold fluid flow rate allows you to calculate the heat exchange capacity and ensure that the heat exchanger meets the thermal requirements of the application.

| Plate Material | Suitable Fluid |

| Stainless steel (SUS304, 316L etc.) | Pure water, River water, Edible salt water, Mineral oil |

| Titanium, Ti-pd | Brine, sea water, Salt water |

| SMO254 | Dilute sulphuric acid, Salt water solution, Inorganic aqueous solution |

| Ni | High temperature, High concentration of caustic soda |

| Hastelloy (C276, C22) | Concentrated sulfuric acid, Hydrochloric acid, Phosphoric acid |

| Main Body Gasket | Operating Temperature (℃) | Suitable Fluid |

| NBR | -15 ~ +135 | Water, Sea water, Mineral Salt, Brine |

| EPDM | -25 ~ +180 | Hot water, Vapour, Acid, Base |

| F26 | -25 ~ +230 | Acid, Base, Fluid |

| FTP | 0 ~ +160 | Concentrated acid, Base, High temperature oil, Vapour |